Industrial Display

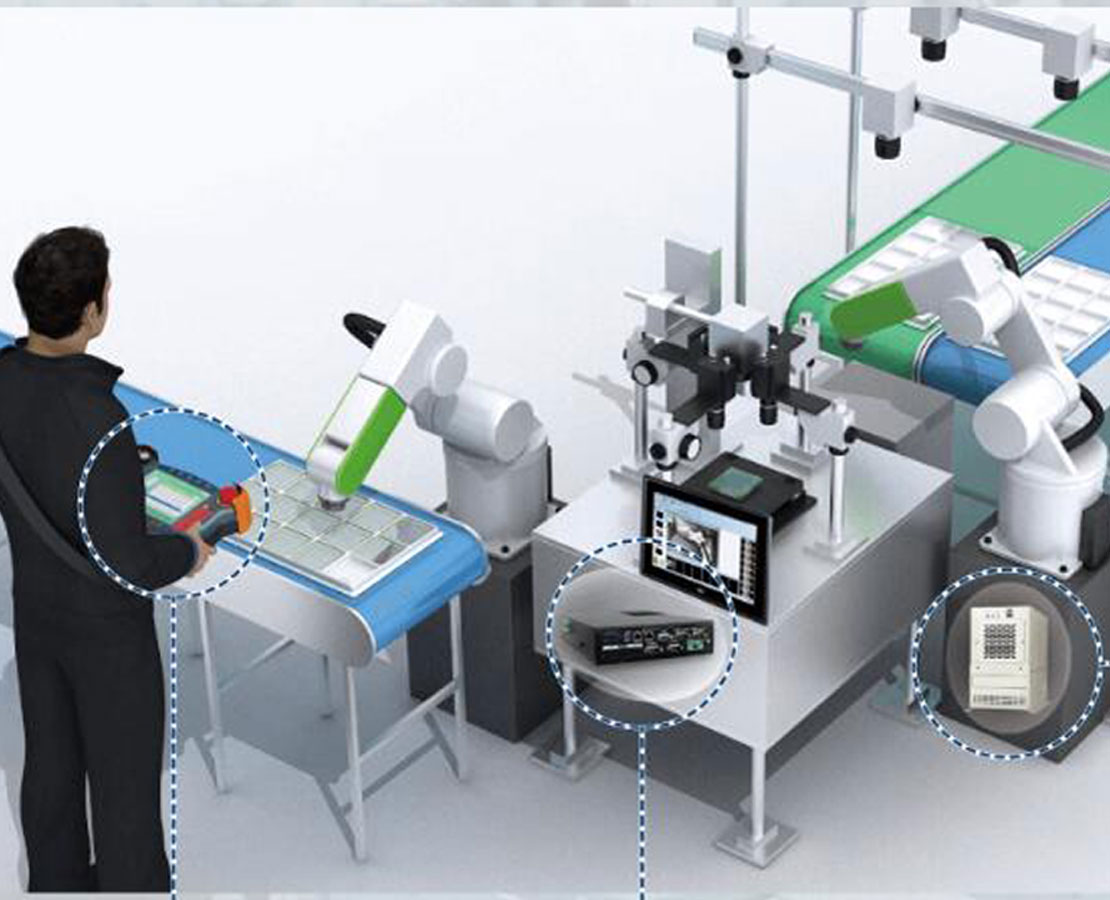

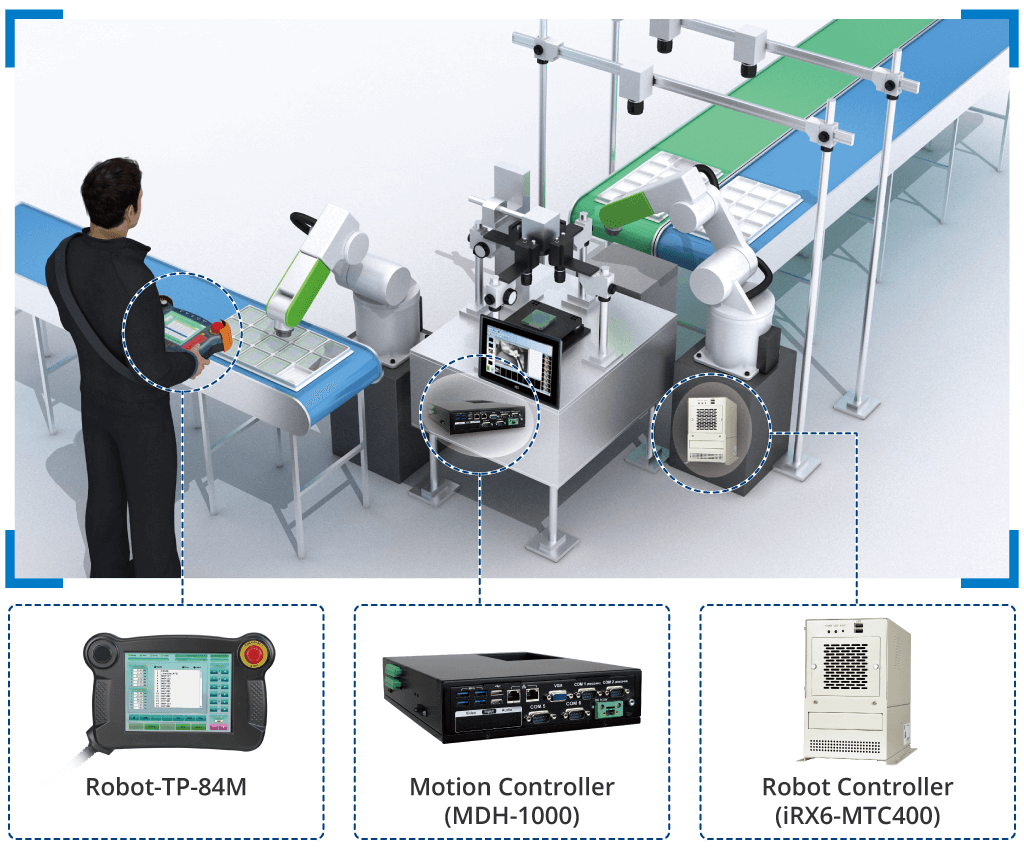

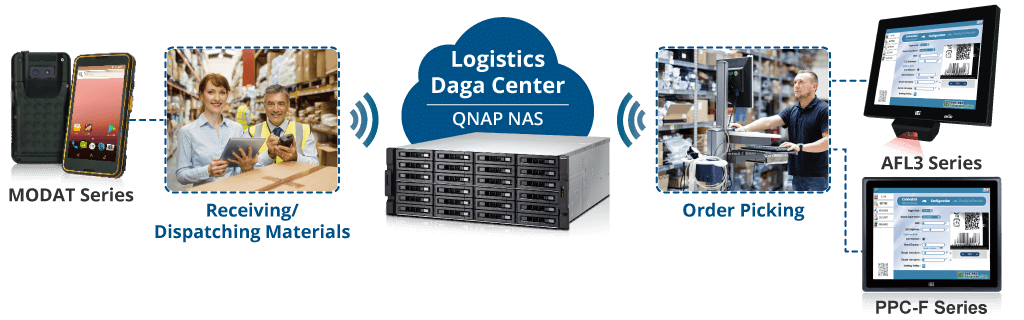

Durable waterproof displays are essential in today’s commercial and industrial applications. IEI’s versatile lines of flat-bezel IP 65 compliant industrial displays with shock and vibration resistance are designed specifically to endure the rigorous demands of modern commerce and industrial environments. These displays are easily integrated into automation applications, ATM machines and human machine interfaces.

View more